Order & Production Process in Details :

01. Enquiries

Receiving of enquiry is the first process. An enquiry with full details of the product is the best way to get fast quote which significantly saves time to get back on the customers requirements.

A detailed enquiry includes:

Quantity or actual pieces required in different break up.

Bag size with Width, Height & Gusset/Sides of the bag.

Fabric quality in Natural/ Dyed with specific color, Laminated/ Un-laminated, Starched or Bleached.

Handle style with end to end size. Any other bag accessories / details.

Print artworks with number of colours to be printed each side. Positioning of artwork.

Shipping terms FOB, CIF, CNF and DDU.

02. Quotation

Once we receive all the details we quote rate for the bag.

We understand our products well and have amongst the fastest quote response system for the same.

This reduces the time to get back to the final customers significantly.

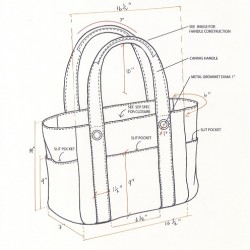

03. Layout Proof

A Layout proof is the third process of our production cycle. A Layout proof means a picture representation of the product discription. This is a very important aspect of the overall process.

After confirmation of order we will send you “Layout Proof” or Digital Blue print of the bag which includes-

1) Make & dimensions of the bag and handle,

2) Size & position of the artwork,

3) Printing color codes and

4) Label or tag details before proceeding to sampling

5) Other specific details

A layout proof goes a long way in resolving any product confusion at the initiation stage itself and helps to assure the customers about the product styling.

04. Sampling

Based on the approved layout proof we proceed to prepare the bag sample.

For dyed bags we prepare a natural sample supported with a printed swatch of the dye colour.

For bulk quantities the printed samples are provided free of charge unless significant development costs are involved such as in process or transfer print jobs.

For smaller orders we have a nominal sample development charges.

05. Photo Proof

Once the samples are developed we send across a photo image of the sample for approval followed by dispatch of physical sample.

On the samples being received and approved we move forward with production.

06. Purchase Order and Confirmation

Official Purchase Order document is needed for our banking purpose.

ChandaBags lays great stress on adherence to banking procedures and customs regulations.

Although at times over procedural, it helps to provide all parties involved a sense security in international trading.

07. Production

Dyeing : Any color except the natural color of the fabric, needs to be dyed first. After dyeing, dye molecules have uncut chemical bond with fiber molecules and give the fabric its specific color. We use health friendly azo free dyes.

Lamination : Jute, Juco and Canvas fabric can be laminated using PP or LDPE lamination. The lamination on the inner side of the fabric gives shape to the bag.

Starching : Jute can also be starched using vegetable starch. This also provide firmness to the fabric, but no as lamination.

Cutting : After the fabric is process to the desired finish, it is spread in layers on cutting table and is marked according to the sizings. Cutting machines are used to cut the marked layers to specific sheets.

Printing : Cut sheets are arranged on printing tables and are printed using silkscreens with water-based azo-free colors. The print is the dried and cured.

Stitching : Printed sheets and other parts are stitched to form the bags on stitching machines.

Finishing : Loose threads are remove, bags flattened and shaped to provide a good finish.

Checking : Each bag is individually checked for any defects. Defective bags are rejected or altered.

Packing : Bags are the packed in lots and placed in strong corrugated boxes.

08. Shipping

Our shipping team shall arrange to ship the consignment as scheduled.

Our facility is 30 minutes drive from the Kolkata port and containers are loaded and customs cleared with maximum efficiency.

Post shipping documentation and delivery are tracked and advised on an ongoing basis.